Bioremediation for Wastewater Treatment in Pharma Industries

“It’s an Illusion that the solution to pollution is dilution.”

This is India’s Century!! These words from S. Jayshankar echoed to every horizon of the planet and no single contradiction came, not from even the harshest critiques of India. This phrase is completely true in its sense and the pharmaceutical sector of India has made a tremendous contribution in making this phrase the “brahm vaakya”.

Current Scenario – Motion and Pollution

The Indian Pharma industry ranks 3rd globally in pharmaceutical production by volume which includes segments such as generic drugs, OTC medicines, bulk drugs, vaccines, contract research & manufacturing, biosimilars and biologics. India is a leader in the supply of generic medicine with 20% share globally and also a top market player for low-cost vaccines. 60% of global vaccine production, contributing up to 70% of the WHO demand for Diphtheria, Tetanus and Pertussis (DPT) and Bacillus Calmette–Guérin (BCG) vaccines, and 90% of the WHO demand for the measles vaccine. The future also looks bright as the valuation of this industry will reach 65 billion in 2024 and 132 billion in 2030.

However, growth always comes with a cost, and the cost is sometimes so expensive that even generations can’t repay it. The cost here I am talking about is POLLUTION! India is getting its name chiseled at the world level in almost every sector, even in the pollution one. And I am sure that contrary to other achievements nobody will be proud of India’s 120th rank in the water quality index, which means that 70% of India’s water is contaminated. With pharmaceutical industries being one of the major contributors to it. Despite almost every industry having wastewater treatment plants, the final effluent can’t make it to the permitted parameters.

But then the question arises that if every pharmaceutical industry has a WWTP then why the compliances are not met?

Bioremediation – Exploring the Solutions

The challenges previously mentioned represent significant risks to the sustainability and operation of industries. However, much like a light at the end of a dark tunnel, Bioremediation emerges as a potential beacon of hope. When implemented effectively, it has the potential to revolutionize wastewater treatment. Nevertheless, there is a notable divide in opinions between industrialists and environmentalists regarding such claims. This skepticism is understandable, given that some companies present themselves as bioremediation companies without possessing the necessary expertise or foundational knowledge

So, we need to first understand the core of bioremediation which is the use of microorganisms. Now the readers will wonder that microorganisms are a vast group falling under Protista, do all of them work in ETP? So, this definition should be reframed as the use of the CORRECT microorganisms, especially selective bacteria to treat the wastewater.

To understand this more thoroughly, let’s assume govt decides to establish a township and publishes an order that it requires humans for establishment and hires without any prior classification and specifics. People from any profession or class will be hired generally in such case which will create mismanagement and failure.

Now the same govt. keeps in mind what it requires to establish a township, analyzing the capacity of township, its requirements etc. and publishes an order to hire engineers, doctors, some policemen, security, shopkeepers, mechanics etc., with a particular number. So now there is a 100 % chance that it will make a good, efficient and sustainable township.

This same concept is applied in bioremediation where microbial strains are carefully selected and formulated into a product according to substrate, issues related to it, plant capacity and many other parameters.

Challenges:

1. Tough to degrade Pollutants

Pharmaceutical effluents consist of some of the most tough to degrade compounds and pollutants such as carbamazepine and metformin. Compounds like these consist of NH and cyclic chain groups which makes them tough to degrade.

2. High COD and TDS

Due to the manufacture of drugs and medicines, few of the pharma effluent streams consist of very high COD and TDS up to 1 lakhs ppm which makes ETP operations difficult along with low sustainability of biomass, thereby leading to violation of compliances.

3. Shock Loads

Due to the manufacture of multiple products and constant changes in the constituents of effluent shock load situation is a common occurrence which leads to the sudden collapse of the ETP ecosystem even leading to serious conditions such as septic. Recovery is also very difficult in such situations.

4. Poor MLSS:MLVSS Ratio

Due to the above-mentioned factors, natural biomass finds it difficult to develop to its optimum quantity which leads to poor MLSS:MLVSS ratio, which is one of the most important factors in the degradation of compounds in the secondary system.

5. Foul Odour

Due to the presence of sulphides, mercaptans and other odour inducing compounds which mostly go undigested release a very foul and pungent odour which sometimes becomes dangerous for human health.

6. Hydraulic Load irregularities

Due to toxic and tough to degrade compounds, the EHS managers find it difficult to run the ETPs up to its maximum capacity which also sometimes affects the production.

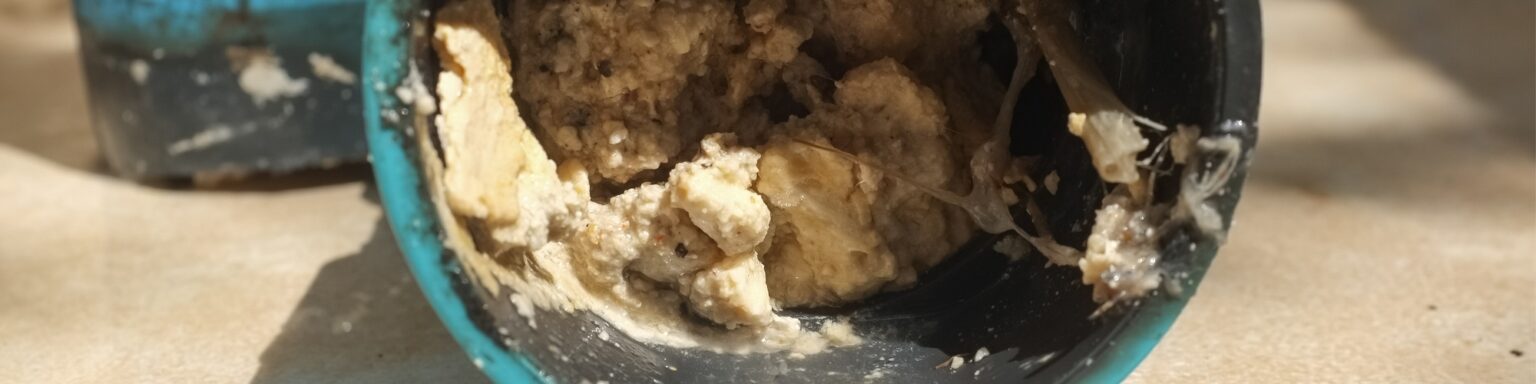

7. Damage to RO/MEE membranes

Due to poor performances of ETPs and especially biological systems, the effluent carrying undigested pollutants eventually damages the membranes in the RO system.

8. Improper Plant design

With excessive pressure from pollution control boards and NGT it has become compulsory for industries having ETP, but many times low-experienced environment consultants suggest improper design thereby creating problems in waste-water treatment overall.

Solutions:

1. Tough to degrade Pollutants -Not so tough

Not so tough before bioremediation as compounds like metformin, carbamazepine and other aliphatic compounds can be easily degraded using the strain of bacteria which synthesizes enzymes like cytochrome P450s, peroxidases, etc. thereby degrading the myths of the afore-mentioned compounds being tough to degrade.

2. High efficiency in High COD and TDS

These high tides of COD and TDS can be easily sailed on the boat of bioremediation using paddles of microbes especially bacteria. Bacteria are not just the most primitive, but one of the toughest organisms who possess the capacity to sustain and perform in high COD and TDS effluent, and degrading higher levels of COD closer to the permissible limits. Often a question is encountered whether bacteria membrane can sustain high amounts of salts or not. To be very specific there are a vast species of bacteria called halophiles which can easily sustain high amounts of TDS.

3. Shock Loads – The Myth Busted

Microbes with the shields of their enzymes can handle these shock waves of notorious effluents with shields of composure like rocks embracing high tides the sea shore. Efficiently working under shocking conditions and maintaining the efficiency of the biological system is one of the USPs of bioremediation. If a microbial consortium with a combination of selective bacteria is being assimilated into the system, then shock load management becomes very smooth enabling faster recoveries. This combination of strains makes sure that even if a different stream of effluent enters the system they act rapidly and maintain the degradation efficiency.

4. From Poor MLSS: MLVSS Ratio – to a Rich one

Bioremediation works towards upliftment of needy biological systems, especially those with poor MMLSS:MLVSS ratio. As explained earlier selective strain bacteria with the capacity to perform under certain conditions effectively maintain their cycle of LAG, LOG and Death phase which combined with efficient RAS (Return Activated Sludge) and WAS (Wate Activated Sludge) management improves the MLSS: MLVSS ratio.

5. Foul Odour – Pushed in past tense

Unfortunately, ETPs/STPs can’t opt for perfumes, but this distress has a savior called bioremediation. The sulphides, mercaptans and other odour-inducing compounds can be easily degraded by bioremediation thereby giving extremely high probability of odour removal.

6. Hydraulic Load irregularities – From irregularities to punctualities.

Since the toxic and tough-to-degrade compounds easily be managed by bioremediation as explained before the EHS managers find it smooth to run the ETPs up to their maximum capacity which also sometimes can optimize the production.

7. Damage to RO/MEE membranes – Longevity ensured by bioremediation

Bioremediation do possess the tendency to tame the notoriously uncontrolled pollutants by either eliminating them or converting into simpler form like a constitution does to criminals by means of encounters or capital punishments. Due to proper degradation of pollutants at microbial level, regulation of sludge, improved settling, improvement of MLSS:MLVSS the life span of RO membranes and MEE plant increases.

8. Improper Plant design-but a proper solution

Bioremediation is the best example for the concept- “Prosper in the Disaster”. Even if the plant design is improper, bioremediation with proper consultation on process management can manage the functionality of ETP thereby easing the pressures from CPCB/NGT.

Pharmaceutical industries do the noble work of manufacturing lifesaving drugs, products to fight diseases, ailments, traumas and epidemics. But when they need solutions to fight pollution or when they are in distressing time related to pollution agencies make them stand in court like trails and whole and sole blame them for the pollution despite of the efforts by the respective organizations to follow the norms. My message to the complete pharma diaspora is that you need not worry more when comes to pollution control. Bioremediation is there to give you a 360-degree solution that covers deliverance, compliance, sustainability, and cost-effectiveness.

To sum up, bioremediation is the Aspirin, or Nitroglycerine in wastewater treatment that relieves the ETPs from dangers of heavy pollution, plant failures. choking of membranes and non-compliances of the parameters.

Uncertain about how biocultures will handle wastewater treatment in your ETP/STP? Reach out to us today to discover more about our bioremediation technology from our wastewater specialists or schedule an on-site plant visit to assess your current processes in ETP/STP by clicking the button below.

Explore our website at https://www.teamonebiotech.com/t1b-products/wastewater-environmental/ or contact us at +91 8855050575.