Bioremediation in a Lake- a Tourist Hotspot

Introduction:

The lake is present in one of the popular cities of India and is itself a tourist hotspot. Hundreds of tourists visit the lake which is know for its scenic beauty and being one of the centres of attractions, the lake is surrounded by food parks, amusements, restaurants etc. However, during past few months the lake water suddenly started stinking and developed a lot of algae. Since, the lake was under the management of local municipal corporation. They employed physical cleaning along with installation of fountains of aeration but it was of no use. The odour was getting worst day by day thereby causing drop in the number of tourists and impacting the local tourism in terms of economy.

The municipal corporation then approached Team One Biotech to get the proper solution for the deteriorating conditions of the lake. We took a sample of the lake water and analysed it at our R&D lab.

Lake Details:

- Capacity: 300 Million Litres

- Area: 47 acres

- Diameter: 30 sq meters

- COD: 168 ppm

- BOD: 87 ppm

- Ammoniacal Nitrogen: 52 ppm

- Algae: High Concentration

Findings and Challenges:

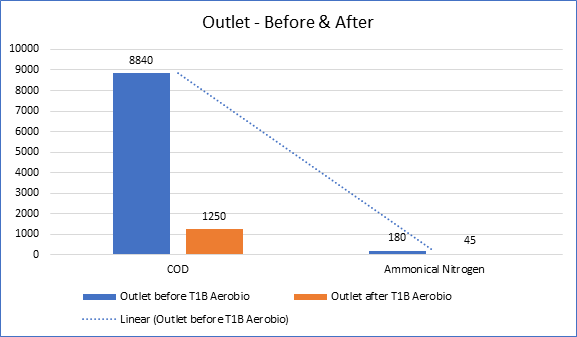

The COD, BOD and Ammoniacal Nitrogen were found to be high in concentration than the discharge limits. Also due to higher amount of AN, the algae growth was increasing rapidly made the water look greenish. Septic like odour was also present, though its source wasn’t initially clear, so we tried to find out any ingresses in the lake. We found that there was an ingress through an overflowing line of sewage nearby causing the lake water to smell and further deteriorating its quality.

The Approach:

After complete study of the lake through on-site visits, water sample analysis and discussions with lake management and municipal corporation, we concluded that the sewage ingress and lack of management in terms of cleaning especially control on waste disposal.A Wastewater Microbiome Analysis (WMA) was carried out before providing a detailed techno-commercial offer. WMA reports of the sample revealed satisfactory growth and development of the microbes in the lake as well as gave us a complete analysis on the exact product and strategy to be employed for effective bioremediation.

Performance Evaluation:

The performance of our solution in lake was evaluated based on various parameters such as chemical oxygen demand (COD), biological oxygen demand (BOD), ammoniacal nitrogen, algae reduction, odor removal and color improvement . The results showed that the ETP was able to achieve the desired effluent quality as per regulatory standards.

The Entire bioremediation program ran for 6 months.

We designed a bioaugmentation and bioremediation programmme which was divided into three parts.

- T1B Lake Cleaner: We planned a 180-day dosing schedule. It included strategic incorporation of T1B lake cleaner. Initially the first 4 weeks were crucial and therefore dosing was kept high to naturally increase the population of healthy microbes. Next 4 weeks and on the amount decreased & the primary agenda for dosing was to maintain a constant population of microbes in the system.

- Physical Cleaning and restrictions on waste disposal: Regular cleaning on lake water from non-biodegradable waste was setup. Strict restriction on waste disposal were also implemented with cooperation from Municipal corporation.

- Monthly monitoring of data and site inspection: Reports of the parameters were sent to us and was scrutinized by T1B to analyse the performance of the product and explore the areas of troubleshooting. On-site inspection was also initiated every fortnite to monitor odor and algae reduction.

Results and discussions:

- We observed 75% reduction in COD and 76% reduction in BOD and and 78.84 % reduction in TAN levels after 180 days.

- Odour was completely eliminate.

- Algae concentration became NIL.

- Tourist footfall increased.

Connect with our experts:

+91 8855050575/sales@teamonebiotech.com